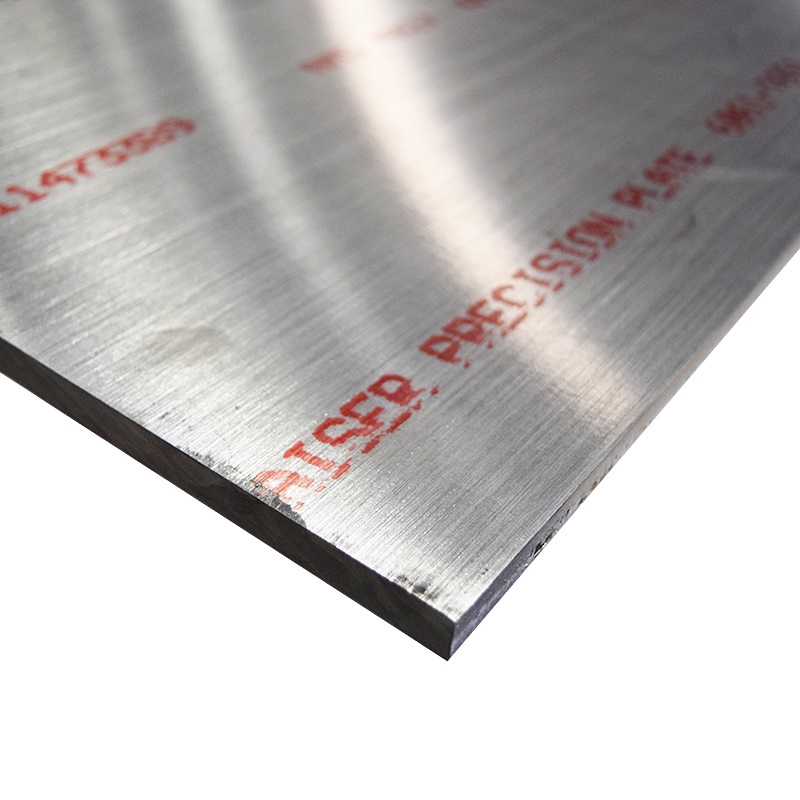

Aluminum Sheet 1050 1×2 m × 0.7 mm

– الواح 1050الومنيوم 1×2×0.7 مم

لوح الومنيوم بيور كود ١٠٥٠ نجع حمادي

535.00 EGP

متاح للحجز (طلب مسبق)

Aluminium 1050

Scope

Aluminium 1050 is a popular grade of aluminium for general sheet metal work where moderate strength is required. Alloy 1050 is known for its excellent corrosion resistance, high ductility and highly reflective finish.

Application

This material is used for chemical process plant equipment, pyrotechnic powder, lamp reflectors, food industry containers, cable sheathing and architectural flashings.

Supplied Forms

Shate

Plain sheet

Plain sheet with a PVC coating on one side

Stucco sheet

Stucco sheet with a PVC coating on one side

Alloy Designations

Aluminium alloy 1050 also corresponds to: AA1050A, S1B and A91050.

Temper Types

The most common tempers for 1050 aluminium are: H14 – Work hardened by rolling to half hard, not annealed after rolling.

Fabrication

Solderability: Excellent

Weldability – Gas: Excellent

Weldability – Arc: Excellent

Weldability – Resistance: Excellent

Brazability: Excellent

Workability – Cold: Excellent

Machinability: Poor

Welding

When welding 1050 to itself or an alloy from the same sub-group the recommended filler wire is 1100. For welding to alloys 5083 and 5086 or alloys from the 7XXX series, the recommended wire is 5356. For other alloys use 4043 filler wire.